GT60 MF Rod

The GT60 MF rod is an essential tool in the field of drilling operations, providing crucial support and efficiency during rock drilling tasks. Its high-strength steel material ensures durability and longevity, making it a reliable and long-lasting tool for various drilling applications. Its lightweight design makes it easy to handle, reducing fatigue for operators and allowing for seamless operation.

GT60 MF Rod: The Ultimate Guide to Choosing the Best Quality Welding Rod for Your Projects

When it comes to welding, the right welding rod can make all the difference in the quality and durability of your work. The GT60 MF rod is one of the most trusted choices among professional welders and DIY enthusiasts. Known for its high strength, versatility, and exceptional welding performance, the GT60 MF rod offers a reliable solution for a wide range of welding applications. In this guide, we’ll explore everything you need to know about GT60 MF rods, their key benefits, applications, and how to choose the best one for your next project.

What is a GT60 MF Rod?

A GT60 MF rod is a type of welding rod designed for use in metal fabrication, welding, and repair applications. The “GT60” classification refers to the rod's material composition, strength, and suitability for specific types of welding projects. The “MF” stands for mild flux, indicating that the rod features a mild flux coating that facilitates smooth welding by protecting the molten weld pool from contamination and oxidation. This ensures cleaner and more reliable welds.

Key Features of GT60 MF Rods

High Strength and Durability

One of the most notable features of the GT60 MF rod is its exceptional strength and durability. This welding rod is specifically designed to withstand high temperatures and intense welding conditions, making it ideal for welding metals that are subjected to heavy stress and pressure. Whether you’re working with steel, iron, or other alloys, the GT60 MF rod guarantees a strong and reliable weld every time.

Superior Fluxing Properties

The flux coating on the GT60 MF rod plays a crucial role in protecting the weld pool from harmful contaminants and oxidation. This ensures a smooth, stable weld, reducing the chances of defects like cracks, porosity, and spatter. The superior fluxing properties of the GT60 MF rod lead to high-quality, clean welds with minimal need for post-weld cleaning and finishing.

Versatility in Welding Applications

The GT60 MF rod is known for its versatility, making it suitable for a wide range of welding tasks. It can be used in a variety of industries, including construction, automotive repair, manufacturing, and heavy machinery. Whether you’re working on structural components, machinery parts, or general fabrication, the GT60 MF rod provides excellent results on a wide array of metals, including mild steel and low-alloy steels.

Easy Handling and Control

Another standout feature of the GT60 MF rod is its ease of handling. The rod is designed to provide a stable and consistent arc, making it easier for welders to control the weld pool. This is especially helpful for beginners who may not have extensive experience with welding. The rod’s smooth arc and stable performance ensure clean, precise welds, even in difficult welding positions.

Benefits of Using a GT60 MF Rod

Reduced Welding Time

The GT60 MF rod is engineered to reduce the time spent on each weld. The high-quality flux ensures faster and more efficient arc stability, which helps speed up the welding process. This is particularly beneficial for large-scale projects where time is a crucial factor, allowing you to complete jobs more quickly and with greater efficiency.

Lower Post-Weld Cleaning Requirements

Welding with the GT60 MF rod results in less spatter and slag, which translates into less time spent on post-weld cleaning and finishing. The smooth welds produced by the rod mean you can focus on more important aspects of the project, saving time and effort while ensuring a high-quality end product.

Cost-Effective Solution

Despite its premium performance, the GT60 MF rod offers a cost-effective solution for welders. It reduces the need for frequent rod replacements due to its durability, making it a budget-friendly choice for long-term use. Additionally, the rod’s low-maintenance characteristics help save on labor and cleaning costs, further increasing its overall value.

High-Quality Welds

The GT60 MF rod produces welds that are both strong and aesthetically pleasing. The minimal amount of spatter and the clean finish of the welds ensure that your work not only performs well but also looks great. This is particularly important in applications where weld appearance is a factor, such as automotive and architectural welding.

How to Choose the Right GT60 MF Rod for Your Project

Selecting the right GT60 MF rod is crucial to achieving optimal results in your welding project. Here are some key factors to consider when choosing a GT60 MF rod:

Material Compatibility

The GT60 MF rod is designed for use with a variety of metals, but it works best with mild steel and low-alloy steels. Ensure that the rod you choose is compatible with the materials you are working with to ensure strong and reliable welds.

Welding Position

Consider the welding position—whether flat, horizontal, vertical, or overhead—when selecting a GT60 MF rod. The rod’s classification will determine its suitability for different welding positions, so it’s important to match the right rod to the specific position of your project.

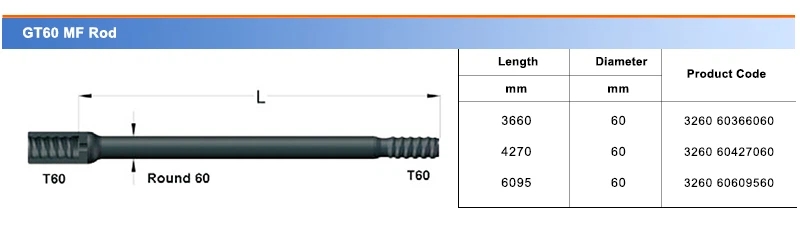

Rod Size and Length

The GT60 MF rod is available in various sizes and lengths, depending on the thickness of the materials being welded and the size of the joint. Be sure to select the appropriate rod size to ensure efficient welding and achieve the desired results.

Welding Equipment

Ensure that your welding equipment is compatible with the GT60 MF rod. These rods are commonly used with stick welding machines, but it’s important to verify that your welder can accommodate the specific voltage and amperage requirements for optimal performance.

Common Applications of GT60 MF Rods

The GT60 MF rod is widely used in various industries and applications, including:

Construction: For welding structural components, beams, and supports.

Automotive: In car repair, restoration, and manufacturing.

Heavy Equipment Repair: Welding parts for machinery like bulldozers, cranes, and excavators.

Manufacturing: For welding industrial machinery, tools, and equipment.

Shipbuilding: In the construction and repair of ships and marine vessels.

Conclusion

The GT60 MF rod is an exceptional choice for anyone seeking a reliable, high-performance welding rod. Its superior strength, excellent fluxing properties, and versatility make it suitable for a wide range of welding applications, from construction to heavy machinery repair. The GT60 MF rod delivers clean, high-quality welds with minimal post-weld cleaning, making it a cost-effective and time-saving option for professional welders and DIY enthusiasts alike.

Whether you’re tackling a large-scale industrial project or a small repair job, the GT60 MF rod offers the durability, efficiency, and quality you need to achieve optimal results. Choose the GT60 MF rod for your next welding project and experience the difference in weld quality and performance.

Application fields:

Application areas include underground mining, construction sites, quarries and tunneling. These areas require the use of efficient equipment and technology for safe and effective work processes. Tools such as excavators, loaders and blasting equipment play a key role in these applications, helping to increase productivity and ensure safety in the workplace.

WHATSAPP

WHATSAPP