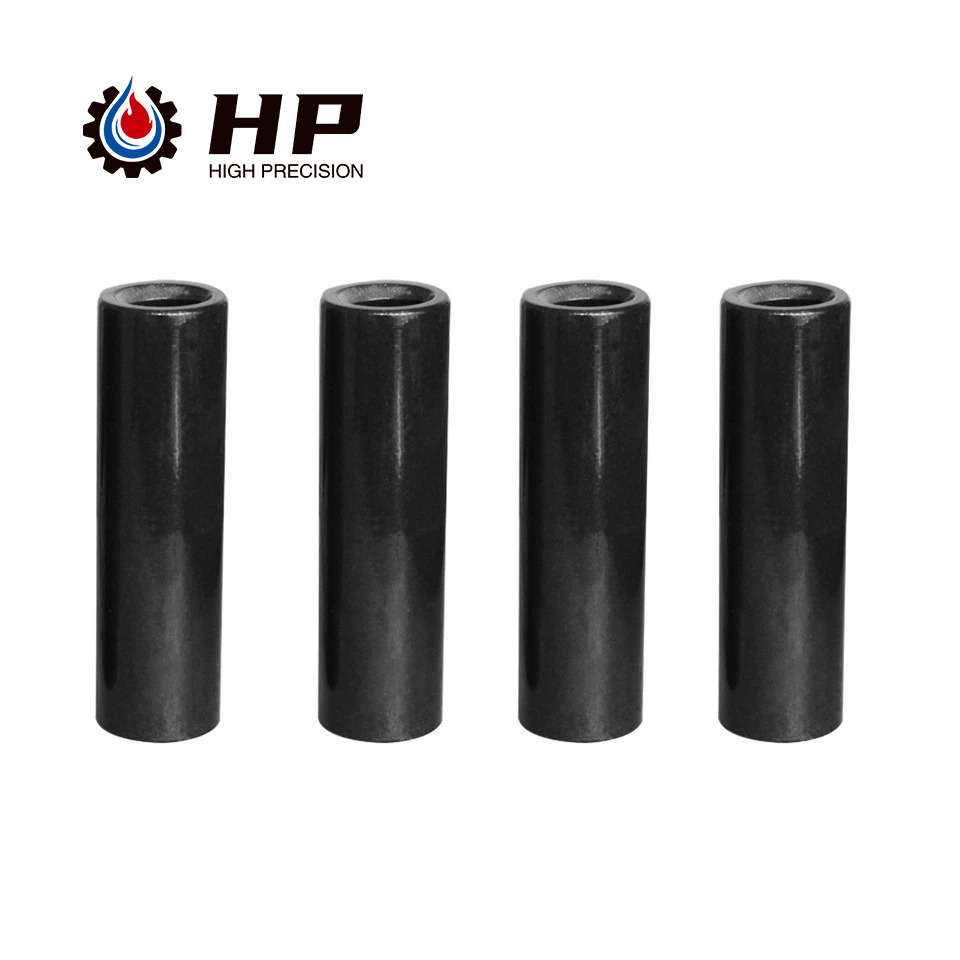

R32 Thread Coupling Sleeve

R32 Threaded Connection Sleeves are made from a high quality alloy steel material, which has excellent strength and durability and is capable of withstanding high-intensity torque transfer and connection operations. The alloy steel material also has good abrasion resistance and deformation resistance, and is able to maintain stable performance in harsh geotechnical environments.

The R32 thread coupling sleeve is a vital component in modern top hammer rock drilling systems. It is specifically engineered to connect two R32 threaded drill rods securely, delivering precision, strength, and drilling stability across various applications. Whether in mining, tunneling, or construction, the R32 thread coupling sleeve ensures consistent energy transmission and maximum operational efficiency.

In this article, we explore the features, applications, benefits, and sourcing considerations of the R32 thread coupling sleeve, emphasizing why it's an indispensable tool in the drilling industry.

What is an R32 Thread Coupling Sleeve?

An R32 thread coupling sleeve is a steel coupling used to join two male-ended drill rods with R32 thread. Manufactured from high-grade alloy steel and treated for durability, the R32 thread coupling sleeve provides a robust and secure connection for high-frequency, high-impact drilling operations.

This coupling is critical for maintaining axial alignment and torque resistance during deep-hole drilling, enabling smooth, vibration-reducing operations in demanding rock formations.

Key Features of R32 Thread Coupling Sleeve

✅ Standard R32 Thread Pattern

Ensures perfect compatibility with R32 rods and bits.✅ Precision Machined Internal Threading

Guarantees tight, secure fitting for maximum energy transfer.✅ High-Grade Alloy Steel Construction

Offers outstanding wear and fatigue resistance, even in abrasive environments.✅ Heat Treatment & Surface Hardening

Enhances service life and reduces the risk of premature failure.✅ Available in Full-Bridge and Semi-Bridge Designs

Customizable for different drilling needs and string configurations.

These features make the R32 thread coupling sleeve a preferred choice in mid-diameter drilling tasks that require accuracy and endurance.

Applications of R32 Thread Coupling Sleeve

The R32 thread coupling sleeve is widely used in a variety of top hammer drilling operations, including:

🏗️ Underground Mining

Perfect for drift and production drilling using R32 rods and bits.

🚇 Tunneling and Metro Construction

Ideal for face drilling, bolt hole drilling, and ground consolidation.

🛠️ Geotechnical Engineering

Used in rock reinforcement, anchoring, and soil nailing systems.

⛏️ Quarry Blasting

Efficiently connects rods for surface bench drilling and blast hole applications.

In every scenario, the R32 thread coupling sleeve enhances drilling efficiency and reduces connection failure.

Benefits of Using R32 Thread Coupling Sleeve

🔩 Improved Drill String Integrity

⚙️ Minimized Rod Loosening or Vibration

🛡️ Reduced Equipment Downtime

💰 Lower Operational Costs

📈 Higher Penetration Rates

The R32 thread coupling sleeve helps maximize the performance of your drilling system while reducing long-term costs.

How to Choose a Reliable R32 Thread Coupling Sleeve Supplier

When sourcing a R32 thread coupling sleeve, consider the following factors:

Material Standardization – Opt for 42CrMo or equivalent alloy steel.

Thread Accuracy – CNC precision threading ensures tight fit and longevity.

Quality Certification – ISO, SGS, and CE compliance enhance trust.

Customization Support – Ability to modify lengths, bridges, and coatings as needed.

B2B Logistics – Ensure your supplier offers fast delivery and technical after-sales service.

Choosing a trusted supplier means your R32 thread coupling sleeve will deliver consistent results even in extreme drilling environments.

Conclusion: Why R32 Thread Coupling Sleeve is a Drilling Essential

For companies operating in rock drilling, infrastructure, and underground engineering, the R32 thread coupling sleeve is not just a part—it's a performance multiplier. It allows seamless energy transfer, minimizes maintenance, and increases overall drilling efficiency.

If your drilling operations rely on R32 equipment, upgrading to a premium R32 thread coupling sleeve is a smart move toward operational excellence.

WHATSAPP

WHATSAPP