MF Drifter Rod

MF Drift Drill Pipe is manufactured from high quality alloy steel, a material that provides excellent strength and durability to withstand intense drilling operations. Alloy steel also offers excellent resistance to wear and tear, allowing for long-lasting stability and performance in harsh underground environments.

In high-performance top-hammer rock drilling operations, tool precision and durability determine the success of every meter drilled. The MF Drifter Rod (Male-Female Drifter Rod) is a cutting-edge solution engineered for maximum energy efficiency, wear resistance, and cost-effectiveness.

Specifically designed for tunneling, bench drilling, and underground mining, the MF Drifter Rod combines male and female threads in a single rod body, reducing connection points and improving energy transmission over traditional coupling systems.

What Is an MF Drifter Rod?

An MF Drifter Rod is a high-strength rock drill rod used in top-hammer drilling systems, featuring a male thread on one end and a female thread on the other. This design eliminates the need for separate couplings, streamlines the drill string, and reduces the risk of joint failure under high-frequency impact.

Compared to standard extension rods, the MF Drifter Rod provides increased drilling accuracy, reduced vibration loss, and faster rod replacement—making it the preferred choice for operators in demanding drilling environments.

Key Features of MF Drifter Rod

✅ Integrated Thread Design

With male-female threading in a single piece, the MF Drifter Rod minimizes the number of joints in the drill string, leading to smoother energy transfer and fewer wear points.

✅ High Tensile Strength Alloy Steel

Manufactured from premium-grade alloy steel and heat-treated for optimal hardness, the MF Drifter Rod withstands high-impact loads and abrasive rock conditions.

✅ Extended Service Life

By reducing the use of couplings and minimizing thread wear, the MF Drifter Rod extends overall tool life and cuts down on replacement frequency and cost.

✅ Perfect for High-Frequency Drilling

Engineered for use with high-frequency drifters, the MF Drifter Rod enhances performance by maintaining straight drilling paths and maximizing impact energy utilization.

✅ Ease of Handling and Assembly

With fewer parts in the drill string, the MF Drifter Rod reduces rig-up time, speeds up maintenance, and ensures safer, more efficient operations on site.

Applications of MF Drifter Rod

The MF Drifter Rod is widely used in:

Underground mine development and production drilling

Tunnel excavation and face drilling

Surface bench drilling in quarries

Rock bolting systems

Hydropower and infrastructure construction

Its high wear resistance and compatibility with modern rock drilling rigs make the MF Drifter Rod a global industry standard.

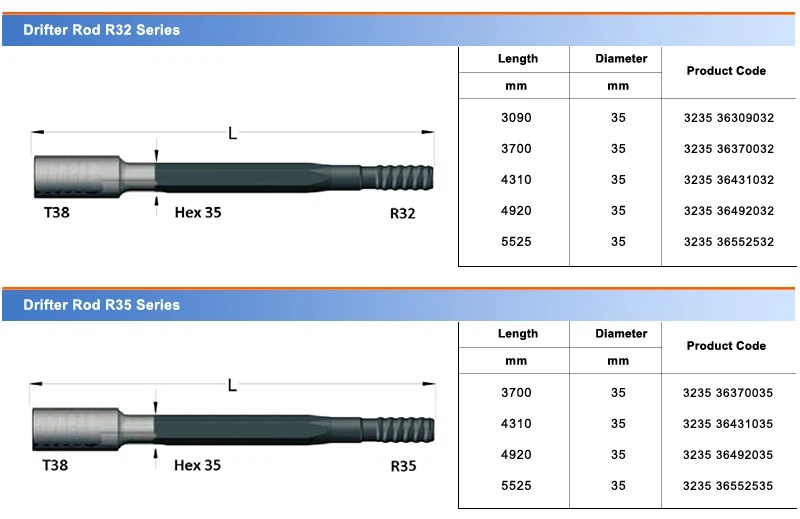

Technical Specifications of MF Drifter Rod

| Attribute | Specification |

|---|---|

| Material | High-tensile alloy steel |

| Length | 915mm – 6400mm (custom available) |

| Thread Types | T38, T45, T51, GT60 |

| Diameter | 38mm – 60mm |

| Application | Top-hammer drilling |

| Surface Treatment | Black oxide, anti-rust coating |

| Thread Hardness | ≥ HRC 50 (after heat treatment) |

Each MF Drifter Rod is produced under strict ISO manufacturing standards and undergoes 100% inspection for thread integrity, straightness, and mechanical properties.

Advantages of Using MF Drifter Rod

Fewer Joints = Less Energy Loss

The MF configuration improves drilling efficiency and reduces vibration dispersion.Reduced Operational Costs

Fewer couplings, less downtime, and longer service life translate to better ROI.Improved Hole Accuracy

Less rod deviation and straighter holes increase overall drilling quality.Streamlined Inventory

Operators need fewer accessory parts, simplifying logistics and inventory control.

Why Choose High-Quality MF Drifter Rods?

Investing in premium MF Drifter Rods ensures your drilling operations stay competitive. Top-tier rods are produced with CNC precision machining, advanced quenching techniques, and international quality assurance—ensuring consistent performance across drilling sites.

Reliable manufacturers offer OEM customization, fast delivery, and expert support, enabling smooth integration with your existing drilling systems.

Conclusion

The MF Drifter Rod is the ideal solution for top-hammer drilling projects requiring performance, accuracy, and long-term value. Its innovative male-female design reduces energy loss, minimizes downtime, and enhances productivity across challenging underground environments.

Whether you're working in mining, tunneling, or infrastructure development, choose the MF Drifter Rod for unmatched drilling efficiency and durability.

In tunnelling and geological exploration, MF drift rods are used for drilling geological samples and for geotechnical analysis. These drilling operations require a high degree of adaptability and precision in order to obtain accurate geological information and samples. the MF drift rods are compatible with different types of drilling equipment and provide high-quality drilling results, providing reliable technical support in tunnelling and geological exploration.

Flexibility and Versatility - The wide range of applications for MF Drift Rods is due to their flexibility and versatility in different drilling scenarios. Whether for precise drilling of wall support holes or for geological sample acquisition and analysis, the MF Drift Rods are able to meet complex drilling requirements and provide critical support and assurance for a wide range of underground projects.

WHATSAPP

WHATSAPP