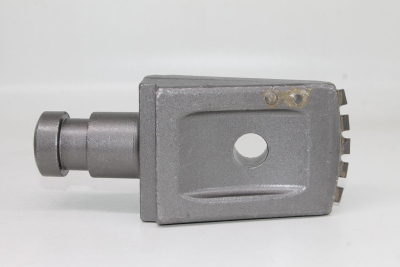

R32 Drifter Drill Rod

R32 Drifter Drill Rod: Enhancing Efficiency and Precision in Drilling Operations

R32 drift drill pipes play a vital role in geotechnical and mining drilling, providing stability, reliability and efficient power transmission for precise drilling operations.

In the world of top-hammer drilling, tool durability, energy efficiency, and operational reliability are paramount. The R32 Drifter Drill Rod is a premium rock drilling component engineered for demanding underground and surface applications. Designed with an R32 thread profile, this drill rod ensures seamless energy transmission, exceptional thread stability, and extended tool life—even under the most rigorous conditions.

For professionals in mining, tunneling, and infrastructure construction, the R32 Drifter Drill Rod offers unmatched performance and value.

What Is an R32 Drifter Drill Rod?

An R32 Drifter Drill Rod is a type of rock drill rod used in top-hammer drilling systems. It features an R32 thread (round 32mm), which is known for its excellent fatigue resistance and secure connection under dynamic loads. These rods are typically used in underground drifting, tunneling, face drilling, and bolting applications, especially where precision and strength are critical.

Unlike conventional rods, the R32 Drifter Drill Rod is manufactured from high-tensile alloy steel and heat-treated for superior performance, ensuring both torque transmission and impact absorption.

Core Features of R32 Drifter Drill Rod

✅ High-Tensile Alloy Steel Construction

Each R32 Drifter Drill Rod is made from specially formulated alloy steel, heat-treated to enhance hardness and fatigue resistance. This allows it to endure high-frequency percussive drilling without distortion.

✅ Precision R32 Thread Profile

The R32 thread ensures tight, reliable coupling between rods and shanks. This thread type is widely recognized for its ability to handle high-torque and impact energy with minimal risk of thread stripping.

✅ Extended Service Life

With exceptional resistance to wear, bending, and breakage, the R32 Drifter Drill Rod delivers long-term performance even in highly abrasive rock formations.

✅ Optimized for Top-Hammer Systems

Designed for use with high-frequency rock drills, this rod ensures efficient energy transmission from drifter to drill bit, improving penetration rates and hole straightness.

Applications of R32 Drifter Drill Rod

Thanks to its versatility and ruggedness, the R32 Drifter Drill Rod is widely used in:

Underground Mine Development

Tunnel Excavation and Face Drilling

Bench Drilling in Quarries

Ground Support and Rock Bolting Systems

Infrastructure and Hydropower Projects

Whether you're drilling in soft sediment or hard rock, the R32 Drifter Drill Rod delivers consistent performance in even the harshest drilling environments.

Technical Specifications of R32 Drifter Drill Rod

| Specification | Details |

|---|---|

| Thread Type | R32 |

| Rod Length | 600mm to 6400mm (custom available) |

| Rod Diameter | 32mm |

| Material | High-strength alloy steel |

| Hardness (HRC) | ≥ 50 (after full-body heat treatment) |

| Surface Finish | Black oxide, anti-corrosion coating |

| Drill Method | Top-hammer |

All R32 Drifter Drill Rods are subject to stringent quality control, including ultrasonic flaw detection, concentricity checks, and thread precision verification.

Why Choose the R32 Drifter Drill Rod?

🔩 Superior Energy Efficiency

The R32 thread profile reduces vibration loss and maximizes impact transfer, resulting in faster penetration and straighter boreholes.

🔧 Reduced Downtime

Its high wear resistance means fewer tool changes and less time lost on maintenance or replacements.

📦 Lower Operating Costs

Longer service life and fewer failures make the R32 Drifter Drill Rod a cost-effective choice over time.

🔄 Easy Compatibility

The R32 standard is accepted worldwide, ensuring compatibility with most top-hammer drilling rigs and accessories.

Conclusion

When accuracy, reliability, and durability matter, the R32 Drifter Drill Rod is the tool of choice for mining engineers, tunnel contractors, and geotechnical teams. Its robust design, secure thread connection, and superior alloy composition make it ideal for both shallow and deep rock drilling applications.

Equip your project with R32 Drifter Drill Rods and experience industry-leading performance with every drill cycle.

Advantage:

The use of R32 drift rods offers significant advantages in several ways. Their precision design ensures accurate and straight drilling, reducing the need for additional heavy labor or corrections. The stability provided by these drill rods reduces tool wear and vibration, increasing drilling efficiency and reducing downtime. Additionally, their reliable connection to drilling equipment enhances safety and operational control, helping to improve the productivity and economics of drilling operations.

In short, R32 drift drill pipes play a vital role in drilling operations, providing stability, precision and efficiency for a variety of drilling applications. Their high quality manufacturing, compatibility with drilling equipment, and durability under demanding drilling conditions make them indispensable tools for achieving optimal drilling results in a variety of industries.

WHATSAPP

WHATSAPP