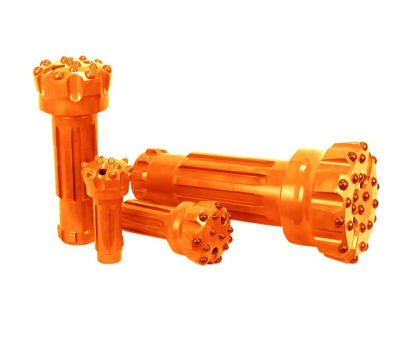

High wind pressure down the hole drill bit

The product is processed by forging with alloy steel as a whole, embedded with high-quality alloy, which can maintain a high drilling speed and high wear resistance when drilling hard and abrasive rocks

High Wind Pressure Down the Hole Drill Bit – Maximizing Deep Rock Drilling Efficiency

In the realm of hard rock drilling and deep borehole operations, the High wind pressure down the hole drill bit has emerged as an essential tool for achieving both penetration speed and durability. Specially designed for high air pressure environments, this drill bit delivers superior energy transfer, optimized chip removal, and unmatched stability in even the toughest formations.

What Is a High Wind Pressure Down the Hole Drill Bit?

A High wind pressure down the hole drill bit is a precision-engineered bit used in conjunction with a DTH hammer under high air pressure. It converts pneumatic energy into mechanical impact directly at the bottom of the borehole, significantly increasing efficiency. The high air pressure not only improves hammer performance but also ensures effective cuttings evacuation, reducing wear and extending service life.

Key features include:

High-grade alloy steel construction

Tungsten carbide button inserts for enhanced hardness

Optimized face designs (concave, convex, flat)

Efficient air flushing systems

The High wind pressure down the hole drill bit is typically deployed in applications such as mining, water well drilling, geothermal exploration, and foundation piling.

Advantages of Using a High Wind Pressure Down the Hole Drill Bit

The High wind pressure down the hole drill bit brings several benefits to demanding drilling environments:

✅ Faster Penetration Rate

High wind pressure allows the hammer and bit to deliver more blows per minute, resulting in quicker progress even through dense rock.

✅ Superior Chip Removal

The high-pressure airflow flushes rock debris efficiently from the hole, preventing re-grinding and reducing wear on the bit.

✅ Increased Drilling Depth Capacity

With better flushing and hammer energy, the High wind pressure down the hole drill bit excels in deep borehole projects.

✅ Enhanced Bit Life

Precision manufacturing and advanced heat treatment techniques extend the lifespan of each High wind pressure down the hole drill bit.

✅ Reliable Performance in Harsh Conditions

Whether facing fractured formations or highly abrasive rock, these bits maintain high impact integrity and hole stability.

Technical Specifications

| Parameter | Typical Range |

|---|---|

| Bit Diameter | 90mm – 305mm (custom sizes available) |

| Shank Type | DHD, QL, SD, COP, Mission, BR, etc. |

| Button Insert Types | Dome, ballistic, parabolic |

| Face Designs | Flat face, concave face, convex face |

| Material | Heat-treated alloy steel + tungsten carbide |

| Operating Air Pressure | 15 – 35 bar (1.5 – 3.5 MPa) |

All components of a High wind pressure down the hole drill bit are built to withstand repeated impacts and maintain geometry under extreme pressure.

Applications of High Wind Pressure Down the Hole Drill Bit

The High wind pressure down the hole drill bit is widely used in several industries:

Mining and Quarrying: For deep blast holes and production drilling

Water Well Drilling: Achieves greater depth with cleaner boreholes

Geothermal Projects: Penetrates deep bedrock for thermal exchange systems

Construction and Foundation: Used in piling and anchoring operations

Oil and Gas Exploration: Suitable for pre-core drilling stages

Its adaptability across geological conditions makes the High wind pressure down the hole drill bit a top choice for global drilling contractors.

How to Choose the Right High Wind Pressure Down the Hole Drill Bit

To maximize drilling efficiency, choosing the correct High wind pressure down the hole drill bit involves considering:

🔧 Rock Type: Hard, medium, or fractured—each requires a different face design and button type.

🔩 Bit Diameter: Match bit size with hammer size and hole specifications.

🌪 Air Pressure Available: Ensure your air compressor can support high wind pressure levels.

🔩 Shank Compatibility: The bit must fit securely with the hammer's shank type.

🛠 Flushing Efficiency: Opt for bits with optimized airflow channels for deeper or dusty conditions.

Customization is often available to ensure that the High wind pressure down the hole drill bit matches your exact drilling conditions.

Maintenance Tips for Long-Lasting Performance

Even the most durable High wind pressure down the hole drill bit requires care:

🛢 Lubricate Air Supply System – Prevents internal wear in the DTH hammer and bit connection

🔍 Inspect Buttons Regularly – Check for flat spots or fractures to maintain cutting speed

🧼 Clean Air Filtration System – Dust in air lines can reduce impact power and damage internal parts

🔩 Torque Couplings Correctly – Prevent thread failure and misalignment

With proper care, a High wind pressure down the hole drill bit can provide hundreds of hours of reliable performance.

Conclusion

The High wind pressure down the hole drill bit is the ideal solution for high-performance drilling where efficiency, precision, and durability are essential. Its ability to convert compressed air into deep, concentrated drilling energy makes it indispensable across modern drilling operations. By choosing the right specifications, maintaining the bit properly, and matching it with suitable hammers, contractors can achieve faster borehole completion and long-term savings.

If you're seeking a top-performing High wind pressure down the hole drill bit for your next drilling project, make sure to prioritize quality, compatibility, and design innovation.

WHATSAPP

WHATSAPP