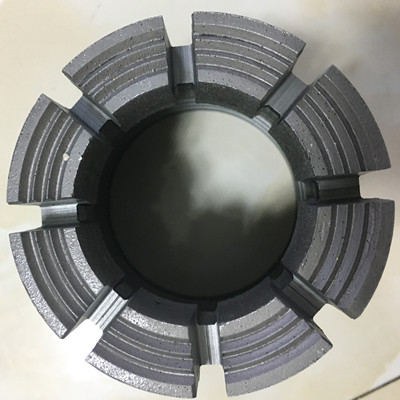

Dome Reaming Bit

Ome reaming bits are a specialized drilling tool utilized to increase the diameter of holes during the drilling operation. These bits are extensively employed in the construction of oil and gas wells, water wells, geothermal wells, and various others. They are commonly used in bench drilling and underground long hole drilling applications alongside extension drill rods and heavy-duty top hammers.

Dome Reaming Bit: The Ultimate Tool for Borehole Enlargement Efficiency

When it comes to precision and performance in borehole enlargement, the Dome Reaming Bit stands out as the go-to solution in the drilling industry. Known for its durability, aggressive cutting ability, and superior stability in hard formations, the Dome Reaming Bit ensures seamless and efficient hole expansion, even in the most challenging geological conditions.

What Is a Dome Reaming Bit?

A Dome Reaming Bit is a specialized reaming tool used to enlarge the diameter of pre-drilled boreholes. Its name is derived from the dome-shaped profile that enhances stability, reduces vibration, and distributes cutting forces evenly. Typically used in down-the-hole (DTH) drilling and top hammer systems, the Dome Reaming Bit is engineered to deliver consistent performance in both vertical and inclined drilling.

Key design characteristics include:

Dome-shaped profile for reduced deflection

Tungsten carbide button inserts for aggressive cutting

Strategic flushing holes for efficient debris removal

High-grade heat-treated alloy steel body

With these features, the Dome Reaming Bit delivers exceptional performance across mining, tunneling, and infrastructure projects.

Advantages of Using a Dome Reaming Bit

Using a Dome Reaming Bit provides multiple operational and economic benefits:

✅ Precision Hole Enlargement

Its symmetrical dome design ensures that borehole reaming is centered, accurate, and consistent—even over long distances.

✅ Reduced Bit Deflection

The Dome Reaming Bit minimizes side forces, which reduces bit walk and keeps drilling on target.

✅ Enhanced Durability

The robust construction and wear-resistant carbide buttons make the Dome Reaming Bit highly durable under extreme loads.

✅ Efficient Rock Cutting

The optimized button layout maximizes rock fragmentation and speeds up the reaming process.

✅ Improved Air Flushing

Its high-pressure air channels remove cuttings efficiently, preventing clogging and minimizing downtime.

Common Applications of Dome Reaming Bit

Thanks to its performance and versatility, the Dome Reaming Bit is widely used in:

Mining Operations: To enlarge blast holes or ventilation shafts

Hydropower and Dam Construction: For deep rock anchoring and foundation work

Oil and Gas Exploration: Pre-enlargement for casing placement

Tunnel Boring Projects: For shaft expansion and anchor bolt installation

Geothermal Drilling: Enlarging boreholes for heat exchange systems

Whether you're working in granite, basalt, or quartzite, the Dome Reaming Bit performs reliably.

Technical Features of Dome Reaming Bit

| Specification | Details |

|---|---|

| Available Diameters | 89 mm – 500 mm (custom sizes upon request) |

| Bit Face Design | Dome reamer profile |

| Button Insert Types | Spherical (for strength), ballistic (for speed) |

| Material | Heat-treated alloy steel + tungsten carbide |

| Air Flushing System | Dual or multi-channel with optimized placement |

| Compatibility | DTH hammers or top hammer rods |

The Dome Reaming Bit is often available with multiple shank types (DHD, QL, SD, Mission) to suit different hammer configurations.

How to Select the Right Dome Reaming Bit

Choosing the proper Dome Reaming Bit depends on several critical factors:

🔩 Original Borehole Size: Select a reamer that matches the enlargement requirement.

🧱 Rock Formation: Hard rock may need spherical buttons; softer layers may benefit from ballistic inserts.

🛠 Drilling Method: Whether using DTH or top hammer drilling affects the bit’s shank and flushing needs.

🌪 Air Supply Capacity: High airflow ensures debris removal and reduces button wear.

🔧 Thread Compatibility: Match your reamer's threads to existing rods or hammers for proper torque transfer.

Proper selection enhances the operational life of the Dome Reaming Bit and maximizes drilling output.

Maintenance Tips for Dome Reaming Bit Longevity

Maintaining your Dome Reaming Bit is vital to achieving long service life and high performance:

🔍 Inspect Buttons Regularly: Look for flat spots or excessive wear.

🛢 Clean Flushing Channels: Remove debris buildup to maintain airflow.

🔩 Check Thread Connections: Ensure tight fit and proper lubrication before each use.

🔧 Avoid Overloading: Monitor RPM and feed pressure to prevent button chipping or body cracking.

Regular maintenance significantly extends the life of your Dome Reaming Bit, reducing replacement costs.

Conclusion

For contractors and drillers seeking precision, power, and durability in borehole reaming, the Dome Reaming Bit is an unmatched choice. Its balanced dome geometry, reinforced construction, and efficient chip removal make it indispensable for modern drilling operations. Whether expanding blast holes in mines or reaming shafts in hydropower projects, the Dome Reaming Bit guarantees performance that meets the highest industry standards.

Don’t compromise on reaming efficiency—invest in a Dome Reaming Bit that delivers results, project after project.

WHATSAPP

WHATSAPP