Tunnel Drill Rod

Tunnel drill rods are critical components in the excavation and construction of tunnels, providing the precision, durability, and adaptability required for drilling in challenging underground environments.

In the complex world of underground excavation, efficiency, precision, and durability are essential. One of the most critical components of any rock drilling system is the Tunnel Drill Rod. Specifically engineered for underground tunneling, mining development, and infrastructure projects, the Tunnel Drill Rod delivers high-performance results under extreme conditions.

Whether you're drilling in soft rock or high-strength granite, the Tunnel Drill Rod ensures maximum penetration rate, torque resistance, and operational reliability—making it a cornerstone tool for modern tunnel construction.

What Is a Tunnel Drill Rod?

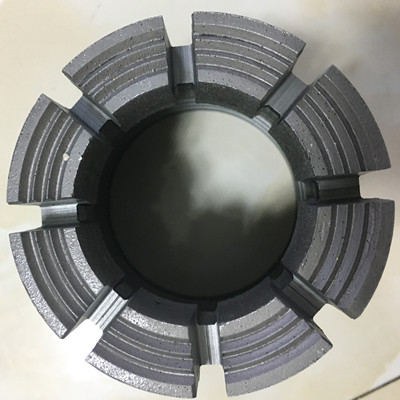

A Tunnel Drill Rod is a heavy-duty steel rod designed for use in underground drilling systems, connecting the rock drill to the drill bit or other drill rods. Manufactured from high-tensile alloy steel and heat-treated for maximum hardness, the Tunnel Drill Rod is built to endure high-impact forces, rotational torque, and harsh underground environments.

Most tunnel drill rods are used in top hammer or DTH (down-the-hole) drilling systems, providing the structural integrity and energy transmission needed to efficiently break rock in tunneling applications.

Key Benefits of Tunnel Drill Rod

1. Unmatched Durability and Strength

The Tunnel Drill Rod is made from top-grade alloy steel with precision heat treatment, ensuring high tensile strength, excellent fatigue resistance, and long service life even under continuous heavy-duty operation.

2. Superior Energy Transfer

The robust construction and perfectly machined thread connections of the Tunnel Drill Rod ensure smooth transmission of impact and rotational energy. This reduces power loss and maximizes drilling efficiency.

3. Optimized for Confined Underground Environments

Specifically designed for narrow tunnels and underground passages, the Tunnel Drill Rod features streamlined dimensions and custom lengths to fit into restricted working spaces without sacrificing performance.

4. Precision Machined Threads

Thread types such as R32, R38, T38, T45, and T51 ensure compatibility with a wide range of rock drilling tools and couplings. The secure thread profile of the Tunnel Drill Rod guarantees connection stability during high-frequency impact drilling.

5. Cost-Effective and Low Maintenance

With high resistance to bending, wear, and corrosion, the Tunnel Drill Rod significantly reduces the need for frequent replacements, offering long-term cost savings and reduced equipment downtime.

Typical Applications of Tunnel Drill Rod

The Tunnel Drill Rod is ideal for a variety of underground drilling operations, including:

Tunnel excavation and rock bolting

Metro, highway, and railway tunnel construction

Underground mining development

Hydroelectric and water diversion tunnels

Infrastructure maintenance and expansion

Its adaptability across different geological conditions and rock hardness levels makes it a trusted choice for engineers and drill operators worldwide.

Technical Specifications of Tunnel Drill Rod

| Specification | Details |

|---|---|

| Material | High-tensile alloy steel |

| Lengths | 600mm – 6400mm (custom available) |

| Thread types | R32, R38, T38, T45, T51 |

| Diameter | 32mm – 51mm |

| Weight | Based on length and thread size |

| Surface finish | Black oxide or anti-corrosion coat |

Each Tunnel Drill Rod undergoes strict quality inspection, including thread gauging, ultrasonic testing, and surface hardness testing.

Why Choose a Quality Tunnel Drill Rod?

Selecting the right Tunnel Drill Rod isn’t just about product quality—it’s about ensuring project success. A well-designed rod enhances drilling speed, accuracy, and safety while reducing wear on equipment and minimizing downtime.

Top manufacturers of Tunnel Drill Rods adhere to international standards and offer product customization, rapid delivery, and full technical support, helping clients meet challenging drilling demands with confidence.

Conclusion

The Tunnel Drill Rod is more than just a drilling accessory—it's a core part of your tunneling success. Designed to perform in tight, demanding, and high-pressure underground conditions, it provides superior energy transfer, structural resilience, and long-term value.

For any tunneling project requiring power, precision, and durability, the Tunnel Drill Rod is the tool of choice.

Key Characteristics of Tunnel Drill Rods

Robust Construction: Tunnel drill rods are constructed from high-strength materials to withstand the demanding conditions of tunnel excavation. Their robust design ensures durability, resistance to wear, and the ability to maintain stability and performance in challenging geological formations encountered during tunneling activities.

Precision Machining: Tunnel drill rods undergo precision machining to maintain straightness and dimensional accuracy. This precision engineering ensures the alignment and accuracy of boreholes, reducing deviations and enhancing the overall efficiency and quality of drilling operations in tunnel construction.

Compatibility and Adaptability: Tunnel drill rods are designed to be compatible with a range of drilling equipment, including drilling jumbos, rock drills, and other tunneling machinery. Their standardized thread connections and adaptability to different drilling setups facilitate seamless integration and efficient operation in diverse tunneling environments.

WHATSAPP

WHATSAPP