Extension Drill Rod

Extension drill rods, also known as extension drill steel, steel bars, or extension bars, are available in hexagonal and round cross-sections. Hexagonal rods offer increased rigidity, weight, and energy transfer efficiency, leading to improved flushing. On the other hand, round rods are generally lighter and are commonly used in extension drilling applications. Longer extension rods tend to have larger diameters. Conventional extension steel is characterized by duplicate threads on each end of the steel.

In the field of mining, tunneling, and quarrying, maintaining drilling precision and efficiency in deep-hole operations is crucial. The Extension Drill Rod stands as an essential component in rock drilling systems, engineered to extend drilling depth without compromising torque transmission or energy efficiency.

Whether in surface drilling or underground development, a reliable Extension Drill Rod ensures consistent performance, longer service life, and reduced operational downtime—making it a vital asset for high-demand drilling environments.

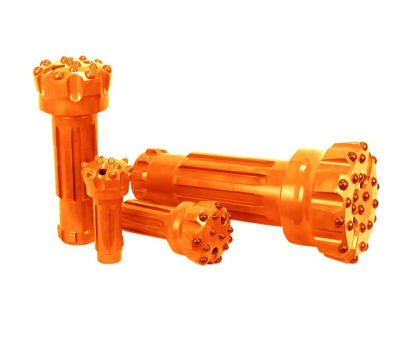

What Is an Extension Drill Rod?

An Extension Drill Rod is a steel rod designed to connect between the shank adapter and the drill bit (or between two rods), extending the overall reach of the drilling system. It is typically manufactured from high-tensile alloy steel, precision heat-treated for maximum hardness and fatigue resistance.

Used in conjunction with thread coupling sleeves and rock drill bits, the Extension Drill Rod ensures the seamless transmission of impact energy from the rock drill to the rock surface, even across extended drilling lengths.

Key Features of Extension Drill Rod

1. High Strength and Toughness

Crafted from premium-grade alloy steel, the Extension Drill Rod features exceptional tensile strength and wear resistance. This ensures its stability under high-pressure drilling conditions and minimizes the risk of bending or breakage.

2. Precision Threading for Secure Connections

Thread ends—typically R32, T38, T45, T51, or ST58—are precision-machined to ensure tight and reliable connections. The secure thread design of the Extension Drill Rod eliminates energy loss and ensures smooth, uninterrupted drilling.

3. Optimal Energy Transfer

The Extension Drill Rod is engineered for efficient energy transmission, enabling powerful impact delivery from the rock drill to the bit tip. This results in faster penetration rates and improved drilling productivity.

4. Corrosion and Fatigue Resistance

Each Extension Drill Rod undergoes a specialized heat treatment and surface hardening process, enhancing resistance to corrosion, wear, and fatigue cracking—critical for extended service in harsh environments.

5. Customizable Lengths and Threads

Available in standard lengths (600mm to 6400mm) and various thread types, the Extension Drill Rod can be tailored to meet specific drilling depths and machinery requirements.

Applications of Extension Drill Rod

The Extension Drill Rod is indispensable in a range of applications, including:

Bench and production drilling in open-pit mines

Underground tunneling and development

Quarrying and aggregate drilling

Construction foundation drilling

Exploration and geothermal drilling

Whether operating with hydraulic top hammer rock drills or pneumatic rigs, the Extension Drill Rod plays a central role in ensuring depth accuracy and structural integrity during the drilling process.

Technical Specifications of Extension Drill Rod

| Parameter | Specification |

|---|---|

| Material | Premium alloy steel |

| Lengths | 600mm–6400mm |

| Thread types | R32, T38, T45, T51, ST58 |

| Diameter | 32mm–51mm |

| Surface Treatment | Heat treated & hardened |

| Weight | Based on length & diameter |

The Extension Drill Rod can be paired with various bits and shank adapters for specific rock formations and drilling conditions.

Why Choose High-Quality Extension Drill Rods?

Using a durable and well-engineered Extension Drill Rod translates to reduced tool replacements, enhanced drilling accuracy, and significant cost savings over time. Inferior rods may twist, crack, or wear out quickly, leading to unplanned downtime and increased maintenance costs.

Reputable manufacturers offer strict quality control, including ultrasonic flaw detection, hardness testing, and thread inspection—ensuring each Extension Drill Rod meets the industry's highest performance standards.

Conclusion

When drilling deep into rock formations, there’s no room for compromise. The Extension Drill Rod provides the strength, precision, and durability needed for high-performance drilling operations across mining, quarrying, and construction sectors. Its ability to maintain energy efficiency over extended depths makes it the preferred choice for professionals worldwide.

Choose a quality Extension Drill Rod for your next project, and drill deeper, faster, and more reliably—every time.

Fully carburization is a critical process utilized to harden the entire surface of the rod, both internally and externally. This process serves to strengthen the rod and extend its operational life, ensuring durability and reliability in demanding drilling environments.

Overall, extension drill rods play a crucial role in various drilling applications, offering versatility, durability, and efficient energy transfer. Their design and construction contribute to the effectiveness and longevity of drilling operations, making them essential components in the field of rock drilling and excavation.

WHATSAPP

WHATSAPP