High Performance Integral Drill Rod

Integral drill pipe plays an important role in rock drilling field with its excellent design features and many advantages. It not only improves drilling efficiency and accuracy, but also reduces maintenance costs, providing solid and reliable technical support for rock drilling operations.

High Performance Integral Drill Rod: The Ultimate Tool for Efficient Rock Drilling

When it comes to rock drilling in mining, quarrying, and construction, tool performance directly affects cost-efficiency, project speed, and safety. That’s why choosing a high performance integral drill rod is critical. Engineered for strength, precision, and durability, the high performance integral drill rod is the go-to solution for operators seeking maximum penetration, minimal downtime, and long service life.

In this comprehensive guide, we will explore everything you need to know about the high performance integral drill rod, from its core features and applications to expert tips on selection and maintenance.

✅ What Is a High Performance Integral Drill Rod?

A high performance integral drill rod is a one-piece drilling tool that combines the drill bit and the rod into a single unit. Unlike threaded systems, this integrated design eliminates the need for connecting couplings, reducing energy loss and increasing drilling accuracy.

The high performance integral drill rod is commonly used with hand-held rock drills or small pneumatic and hydraulic rigs, especially in tunneling, slope support, secondary blasting, and small bench drilling operations. Its streamlined structure enhances energy transfer and allows for smoother, faster penetration into hard rock formations.

🔍 Key Features of High Performance Integral Drill Rod

1. One-Piece Design

The integrated design eliminates connection weak points and enhances energy transfer from drill to rock, maximizing drilling efficiency.

2. High-Strength Alloy Steel

The high performance integral drill rod is forged from premium alloy steel, heat-treated to deliver exceptional hardness, tensile strength, and fatigue resistance under extreme conditions.

3. Precision-Machined Carbide Tips

Equipped with tungsten carbide drill heads, the rod ensures high wear resistance and extended service life even in the most abrasive rock formations.

4. Optimized Length and Diameter

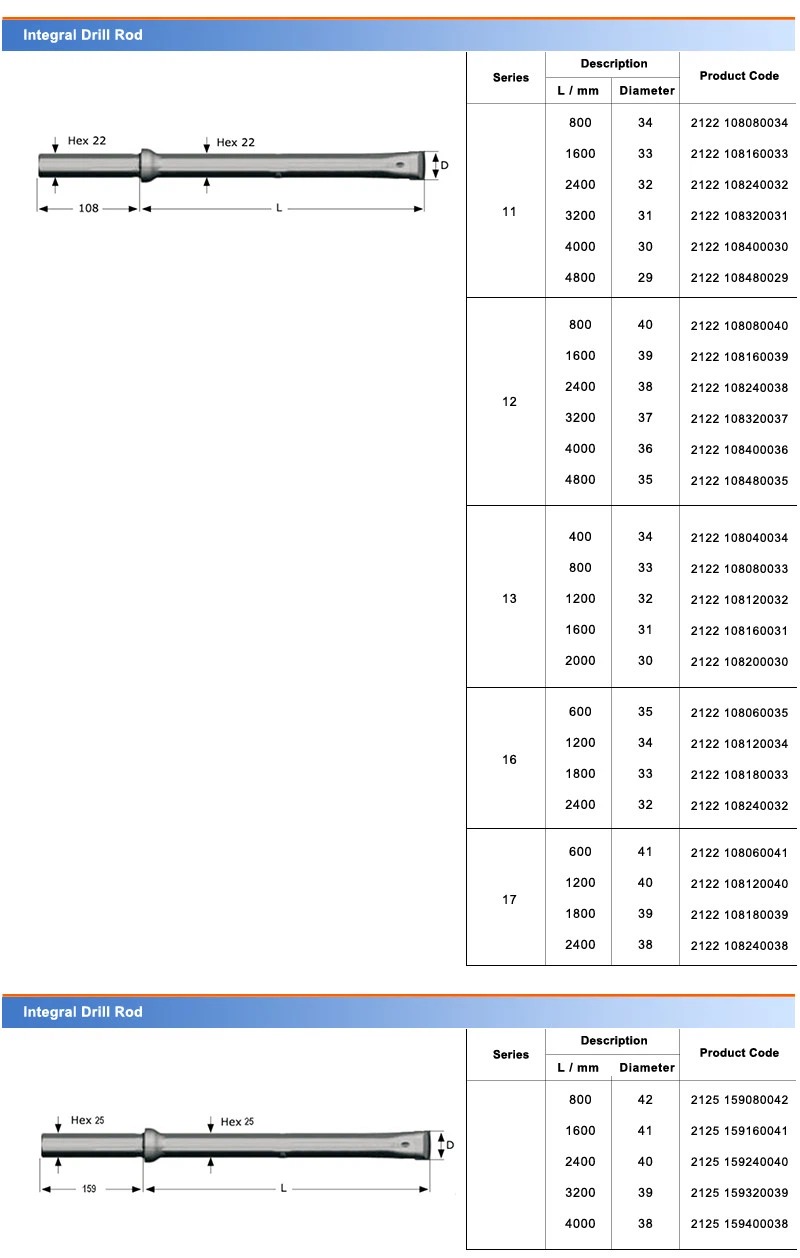

Available in various lengths (400 mm to 8000 mm) and diameters (22 mm, 25 mm, 28 mm, 32 mm), the high performance integral drill rod offers options for every type of drilling requirement.

🚀 Benefits of Using a High Performance Integral Drill Rod

✅ 1. Increased Drilling Efficiency

The seamless design of the high performance integral drill rod allows more impact energy to reach the drill bit, significantly boosting the penetration rate.

✅ 2. Reduced Operating Costs

With fewer replaceable parts and longer service intervals, the high performance integral drill rod minimizes the need for frequent replacements and maintenance.

✅ 3. Lower Fuel and Air Consumption

Because it transmits energy more efficiently, the high performance integral drill rod reduces the power demand from compressors or hydraulic systems, saving fuel or air consumption.

✅ 4. Superior Borehole Straightness

Its rigidity and vibration control result in straighter holes, which is crucial for controlled blasting and structural support operations.

✅ 5. Enhanced Worker Safety

By eliminating loose coupling joints, the high performance integral drill rod lowers the risk of tool breakage and operational failure, creating a safer working environment.

🏗 Common Applications of High Performance Integral Drill Rod

The high performance integral drill rod is used extensively across industries where hard rock drilling is required:

Mining and Tunneling: For development drilling, shaft sinking, and secondary blasting.

Quarrying: In granite, basalt, and limestone extraction.

Hydropower and Dam Projects: For anchor hole and grouting operations.

Slope Stabilization and Bolting: Where precise drilling and long rods are required.

Road Construction: For cutting through rock in mountainous terrain.

Its adaptability and performance make it a preferred choice in high-demand environments.

🔩 How to Choose the Right High Performance Integral Drill Rod

When selecting a high performance integral drill rod, consider the following:

1. Drill Rig Compatibility

Ensure the rod matches your rock drill’s shank size and power rating. Common shank types include 22x108mm and 25x108mm.

2. Rock Hardness

Select rods with carbide grades and steel hardness suited for the rock type (e.g., softer grades for sedimentary rock, harder grades for granite and basalt).

3. Drilling Depth

Choose the rod length based on your required borehole depth. Shorter rods are ideal for control, while longer rods improve reach and reduce rod changes.

4. Bit Shape and Diameter

Pick the right bit shape—cross-type or chisel-type—for your formation. The high performance integral drill rod comes with various head styles to meet specific drilling goals.

🧰 Maintenance Tips for High Performance Integral Drill Rod

Proper maintenance of your high performance integral drill rod ensures consistent performance and longevity:

Regular Inspections: Check for surface cracks, wear on carbide tips, and rod straightness.

Storage: Store in dry, cool places to prevent corrosion and warping.

Sharpening: Use a carbide grinder to keep tips sharp for optimal cutting speed.

Lubrication: Apply anti-seize lubricant on shanks to prevent sticking and reduce friction during operation.

🏆 Why Industry Leaders Trust the High Performance Integral Drill Rod

The high performance integral drill rod is trusted globally for its unmatched durability, efficiency, and reliability. It reduces operational costs, increases penetration speed, and improves borehole quality—all while ensuring operator safety. Whether you're working in underground mines or open-pit quarries, this tool outperforms traditional rod-and-bit systems in both performance and value.

📦 Where to Buy High Performance Integral Drill Rods

When sourcing a high performance integral drill rod, choose suppliers with:

ISO-certified manufacturing

In-house quality inspection

Custom specifications on demand

Technical support and after-sales service

A premium high performance integral drill rod from a reputable manufacturer ensures consistency, strength, and extended usage in harsh drilling conditions.

📌 Final Thoughts

The high performance integral drill rod is more than just a drilling accessory—it’s a game-changing solution that enhances efficiency, reduces costs, and improves safety in hard rock drilling. Its robust design, precision engineering, and energy transfer capabilities make it an essential tool for serious operators in the mining, quarrying, and infrastructure industries.

Integral drill pipe has many advantages in rock drilling operations:

Improved drilling efficiency: the design and material of the integral drill pipe enables it to transmit drilling power quickly and stably, which improves drilling efficiency and reduces operation time.

Reduced maintenance costs: Due to the more robust structure of the integral drill pipe, the cost of use and maintenance is relatively low, reducing the need for frequent replacement of drilling tools.

Accurate drilling position: The stability of the integral drill pipe and the precise transmission of drilling force can ensure the accuracy of the drilling position and improve the precision of rock drilling.

WHATSAPP

WHATSAPP