Integral Rods

Integral Drill Rods: Engineered for Reliability & Maximum Drilling Value

Unmatched Reliability – One-piece forged construction eliminates weak threaded joints, drastically reducing breakage and maximizing impact energy transfer.

Superior Toughness & Wear Resistance – Made from high-strength alloy steel for exceptional durability and the longest service life in demanding conditions.

Fits All Major Drills – Available in various head and shank designs to ensure perfect compatibility with your existing rock drills and applications.

Higher Penetration Rates – Seamless design minimizes energy loss, delivering faster drilling and boosting job site efficiency.

Lower Cost-Per-Meter – Reduced failures and downtime translate directly to excellent ROI and the best value over the rod's lifetime.

Product Overview: Redefining Drilling Simplicity and Durability

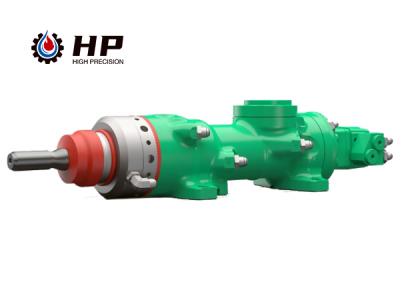

Integral Rods represent a fundamental advancement in rock drilling tool technology, engineered specifically for applications demanding maximum reliability and operational efficiency. As a cornerstone tool in modern mining, quarrying, tunneling, and construction projects, they are designed to deliver superior performance where durability and consistent power transmission are non-negotiable. Unlike conventional extension drill rod systems or threaded drill steel assemblies, the Integral Drill Rod is, as its name implies, a single, solid piece of high-grade alloy steel. In this monolithic design, the drill bit (or integral head) and the striking shank are forged directly onto the rod body, creating a seamless, unitary drilling tool.

This innovative one-piece construction eliminates the threaded or coupled connections found in multi-part systems, which are the most common points of mechanical failure and energy loss. By removing these weak links, Integral Rods ensure that impact energy from the drill rig is transferred directly and efficiently to the rock face, minimizing energy dissipation and maximizing penetration rates. Primarily used with pneumatic jackhammers and lightweight to medium rock drills, these rods are the optimal choice for drilling shallow to medium-depth blast holes, anchor holes, bolting holes, and exploration holes. The core value proposition is clear: enhanced drilling efficiency, reduced downtime from tool failure, and a lower total cost of operation, making them an indispensable tool for contractors focused on productivity.

Key Technical Features and Engineering Specifications

Monolithic Forged Construction for Unmatched Reliability

The defining characteristic of our Integral Rods is its one-piece forged construction. The entire unit—from the precision-machined shank to the hardened drilling head—is hot-forged from a single, premium steel blank. This advanced manufacturing process aligns the steel's grain structure along the rod's contours, creating a continuous flow that significantly enhances toughness and fatigue resistance. This solid, unitary body fundamentally eradicates the failure risks associated with threaded joints, such as cross-threading, stripping, or stress-corrosion cracking. The result is a drilling tool with exceptional structural integrity that can withstand the relentless high-impact forces of rock drilling, ensuring longer service life and consistent performance in the most demanding conditions.

Premium High-Strength Alloy Steel Composition

To endure extreme abrasion and cyclic loading, our Integral Rods are forged from specialized, high-strength alloy steels such as 55SiMnMo and other high-manganese grades. Steel grade 55SiMnMo is particularly renowned in the industry for its optimal balance of properties. It provides a very hard surface layer for superior wear resistance against abrasive rock, while maintaining a exceptionally tough core that absorbs and dissipates impact energy without succumbing to brittle fracture or bending. This material science advantage is critical for resisting impact fatigue and ensuring the rod maintains its straightness and functional integrity over extended use, directly contributing to a longer operational lifespan.

Versatile Head and Shank Design Configurations

To ensure broad compatibility and application-specific performance, our Integral Rods are available in a variety of standardized configurations. The shank design (e.g., H22 × 108mm or H19 × 108mm) is manufactured to exacting tolerances to guarantee a perfect, secure fit in all major brands of rock drills and jackhammers, ensuring efficient energy transfer. Furthermore, the integral head design is offered in several profiles to match the target rock formation:

Chisel Head: A robust, single-wedge design ideal for penetrating soft to medium-hard, non-abrasive rock. It offers a cost-effective solution for general-purpose drilling.

Cross Head (Button Head): This design features multiple, independently set tungsten carbide buttons (typically in diameters from 26mm to 42mm). The carbide buttons provide superior wear resistance and more efficient rock fracturing in hard, abrasive, and highly fractured formations, leading to faster penetration rates and extended tool life.

WHATSAPP

WHATSAPP