Tapered Rock Bit

Underground and open-pit mining operations rely on taper rock bits for their precision drilling capabilities, allowing miners to extract minerals and other resources efficiently and safely. These bits are designed to withstand the harsh conditions of mining environments, providing durability and longevity.

Tapered Rock Bit: The Ultimate Tool for Efficient Rock Drilling

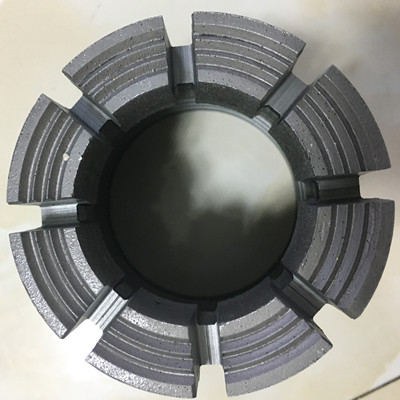

Tapered Rock Bit is an indispensable tool in the drilling industry, renowned for its versatility, durability, and high performance. Designed for a variety of applications, Tapered Rock Bit is commonly used in mining, construction, and geological exploration for drilling hard rock formations. The robust construction of the Tapered Rock Bit ensures precision and reliability, making it the preferred choice for tough drilling environments.

One of the key features of the Tapered Rock Bit is its tapered design, which allows for easy alignment and ensures a secure fit between the drill rods and the bit. This tapered system provides increased stability and reduces the risk of misalignment, ensuring smooth and continuous drilling operations. The design also facilitates quick and easy bit replacement, making the Tapered Rock Bit a highly efficient tool for ongoing operations.

The Tapered Rock Bit is typically made from high-strength alloy steel and features tungsten carbide inserts, ensuring excellent resistance to wear and tear. These inserts are strategically placed in the critical areas of the bit, allowing it to maintain cutting performance even in abrasive and high-impact conditions. Whether you are drilling in soft or hard rock formations, the Tapered Rock Bit is engineered to handle diverse geological conditions with ease.

Another significant advantage of the Tapered Rock Bit is its ability to penetrate deep into rock formations quickly and efficiently. The bit's aggressive cutting action allows it to break through rock layers with minimal effort, reducing the time and energy required for drilling. This not only increases productivity but also lowers overall drilling costs.

Tapered Rock Bits come in a variety of sizes and configurations, making them adaptable to different drilling rigs and requirements. Whether you are drilling vertical or horizontal holes, the Tapered Rock Bit can be customized to meet the specific needs of your project. The tool’s tapered geometry ensures effective chip removal, preventing clogging and maintaining optimal drilling efficiency.

For operators working in demanding conditions, the Tapered Rock Bit is designed for ease of use. The bit’s simple, user-friendly design reduces the complexity of operation and maintenance, making it an ideal choice for both novice and experienced drillers. The Tapered Rock Bit is also designed to provide long service life, minimizing the need for frequent replacements and ensuring that your drilling operations remain uninterrupted.

In addition to its functionality, the Tapered Rock Bit plays a vital role in reducing environmental impact. Its efficient drilling action reduces the energy required for rock removal, leading to lower fuel consumption and fewer emissions. This makes the Tapered Rock Bit an eco-friendly option for modern drilling operations.

In conclusion, the Tapered Rock Bit is an essential tool for any drilling operation that requires precision, durability, and high performance. Its tapered design, high-strength construction, and ability to work in various geological conditions make it a top choice for professionals worldwide. Whether you are drilling in hard rock, soft rock, or abrasive surfaces, the Tapered Rock Bit delivers reliable, efficient, and cost-effective results.

Geothermal water well mining projects also benefit from the use of taper rock bits, as they enable drilling deep into the earth to access geothermal energy sources. The precision and efficiency of these bits contribute to the success of geothermal exploration and extraction efforts.

Blast furnace tapping in the mining industry requires specialized tools like taper rock bits to create openings for extracting molten metal. The high heat and pressure involved in this process demand reliable and durable drilling equipment, making taper rock bits the ideal choice for blast furnace tapping operations.

WHATSAPP

WHATSAPP